polypropylene prosthetic socket

For trans-tibial prostheses a patellar-tendon-bearing PTB socket with a T-strap was used. This article uses the term definitive in relation to sockets to refer to a permanent socket delivered to the patient for long-term use.

This allows practitioners to make lighter stiffer orthoses and prosthetic definitive sockets.

. The other parts of the assistive devices sockets cosmetic covers etc are made out of polypropylene sheets using thermoforming. Polypropylene provides the core for the prosthetic system developed by the ICRC. To investigate the problem of delamination of the socket the tensile properties of the socket material were determined according to ASTM D638-99.

Pelite is a light weight moisture proof sponge foam polypropylene with excellent shock absorption characteristics. Easily formed polypropylene is widely used for body jackets upper and lower extremity orthoses especially AFOs and rigid outer prosthetic sockets. ASTM D638-99 ISO 10328 principal structural tests Polypropylene prosthesis Prosthetic socket Prosthetics Rapid prototyping.

The socket was made by heating a 4mm polypropylene sheet at 170 Celsius for 20 minutes and draping it on the plaster cast covered with a stocking to facilitate suction. Request PDF Structural integrity of polypropylene prosthetic sockets manufactured using the polymer deposition technique Rapid prototyping RP technology has been used recently as a means for. The ultimate tensile strength was.

In addition the OP grade provides a somewhat higher degree of stiffness than standard grade. Polypropylene provides the core for the prosthetic system developed by the icrc. The ultimate tensile strength was found to be approximately 13-23 per cent lower than that of polypropylene sheets that are at present normally used for socket fabrication.

There is an increasing interest in exploiting state-of-the-art 3D printing technology for clinical problem-solving. Using CAD-CAM techniques the production process is consistent and faster. To investigate the problem of delamination of the socket the tensile properties of the socket material were determined according to ASTM D638-99.

Transfer papers that create brighter more visually appealing graphics on. This definitive socket can be constructed from either thermoplastic or thermoset materials. Product description The system is a set of specially designed polypropylene components to fabricatefit lower limb prosthesis artificial limb for people with lower limb amputation.

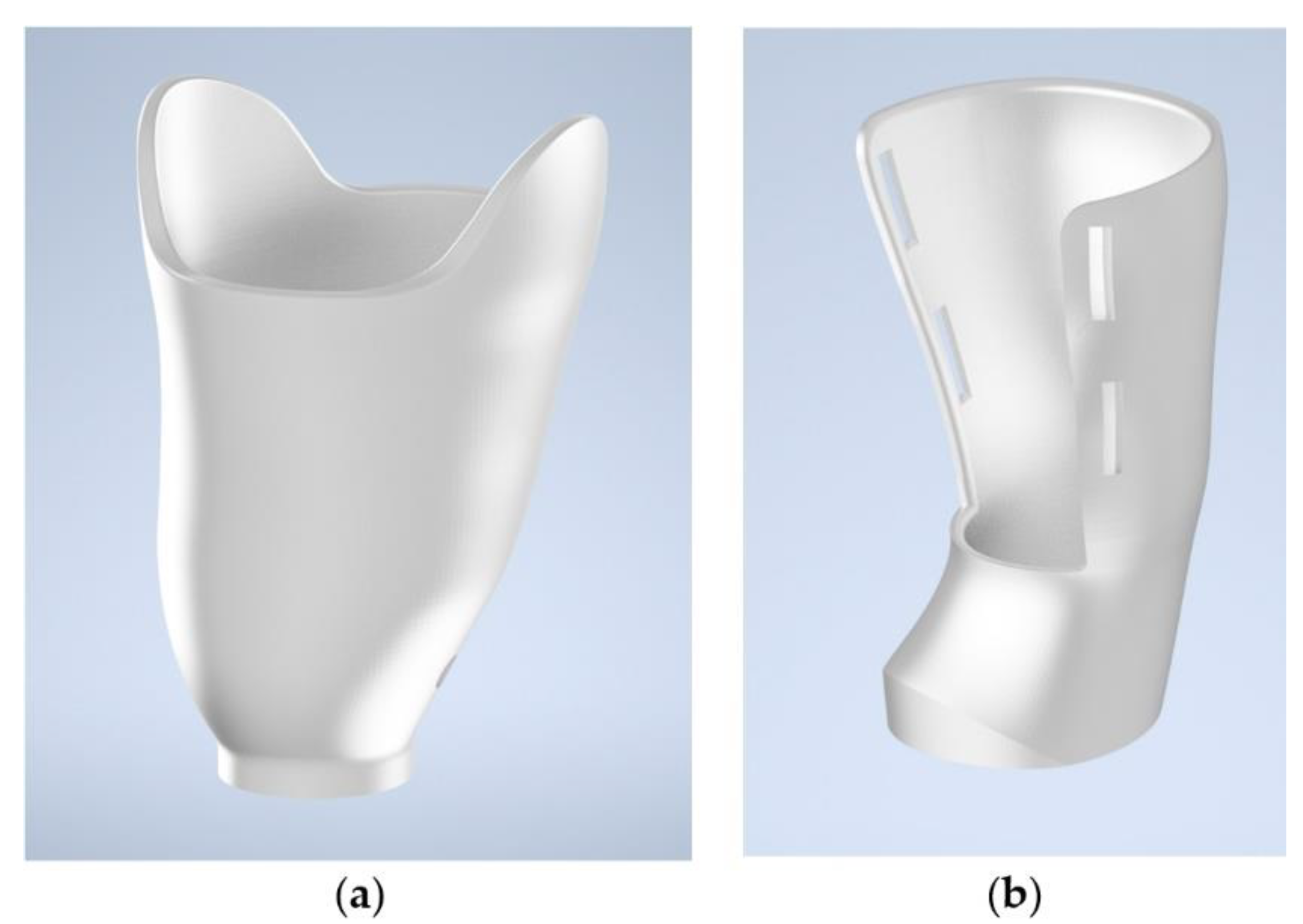

Polypropylene copolymer sockets CPs thermoplastic copolymer are typically used as definitive sockets. This study investigated the structural integrity of polypropylene sockets manufactured using a polymer deposition technique in which a socket is formed by a continuous strand of partially melted polypropylene that is spirally deposited according. No soft socket was made for the trans-tibial prosthesis.

The ultimate tensile strength was found to be approximately 1323 per cent lower than that of polypropylene sheets that are at present normally used for socket fabrication. Copolymer Polypropylene Copoly PP Copolymer polypropylene is a bit softer but it is tougher and. 1 Trans-tibial below-knee and 2.

The patients were followed prospectively for 10 and 19 months. It is available with invisible ventilation holes or with visible perforations. OP Grade Polypropylene is made from a proprietary grade of FDA compliant 100 virgin homopolymer polypropylene that is specially formulated to turn clear when heated which visually aids lab technicians during the thermofor- ming process.

Usually it comes in two varieties. To investigate the problem of delamination of the socket the tensile properties of the socket material were determined according to ASTM D638-99. The injection process is used for making the components.

Structural integrity of polypropylene prosthetic sockets manufactured using the polymer deposition technique. The other parts of the assistive devices sockets cosmetic covers etc are made out of polypropylene sheets using thermoforming. Strand of partially melted polypropylene that is spirally deposited according to the sockets cross- sectional contour.

And an alternative way to design and produce prosthetic sockets is using computer-aided design CAD and computer-aided manufacturing CAM systems 19. Lower extremity orthosis made using this material often comply with Medicare code L 2755. Abstract Thirty-two 32 trained prosthesis users with 34 trans-tibial amputations mostly due to war were fitted with prostheses fabricated from polypropylene PP prosthetic components designed and manufactured by the International Committee of the Red Cross ICRC.

Prosthetic sockets 14 textured sockets and an Original Squirt-Shape OSS Socket were fabricated from polypropylene copolymer using the Squirt-Shape 3D Printer and compared to a smooth socket thermoformed from polypropylene copolymer. It also comes in a wide variety of thicknesses densities and colors. This study investigated the structural integrity of polypropylene sockets manufactured using a polymer deposition technique in which a socket is formed by a continuous strand of partially melted polypropylene that is spirally deposited according to the sockets cross-sectional contour.

The injection process is used for making the components.

Trans Tibial Below Knee Prosthesis With Liner And Components Part Download Scientific Diagram

Natural Homopoly Polypropylene Prosthetic Squares Opc Health

Homopolymer Polypropylene North Sea Plastics

Materials Free Full Text Study On Properties Of Automatically Designed 3d Printed Customized Prosthetic Sockets Html

Plastic Sheet For Orthotics Prosthetics Curbell Plastics

3d Printed Tt Socket Download Scientific Diagram

Materials For Lower Limb Prosthetic And Orthotic Interfaces And Sockets Evolution And Associated Skin Problems

The History Of The Check Socket For Prosthetics Orfit Industries

Lytra Prosthetic Leg Makes Showering Doable For Amputees

Pdf Design And Additive Manufacturing Of Lower Limb Prosthetic Socket

Pdf Sockets For Limb Prostheses A Review Of Existing Technologies And Open Challenges Semantic Scholar

Polymer Long Stump Prosthetic Socket Full Leg Rs 20000 K S Enterprises Id 22625294655

Elle The Incredible 3d Printed Swimming Leg For Amputees 3dprint Com The Voice Of 3d Printing Additive Manufacturing Prosthetics 3d Printing The Incredibles

Copolymer Polypropylene Prosthetic Squares Opc Health

Standard Cyborg Unveils The 3d Printed Prosthetic Water Leg Priced Under 500 3dprint Com The Voice Of 3d Pr Orthotics And Prosthetics Legs Prosthetics

Artifical Leg Below Knee Price Free Prosthetic Leg In India Stanford University Prosthetic Leg Physical Disabilities

A Sample Check Socket Cs Prior To Static Failure Load Testing With Download Scientific Diagram

Comments

Post a Comment